Individual Industry 4.0 solutions for companies

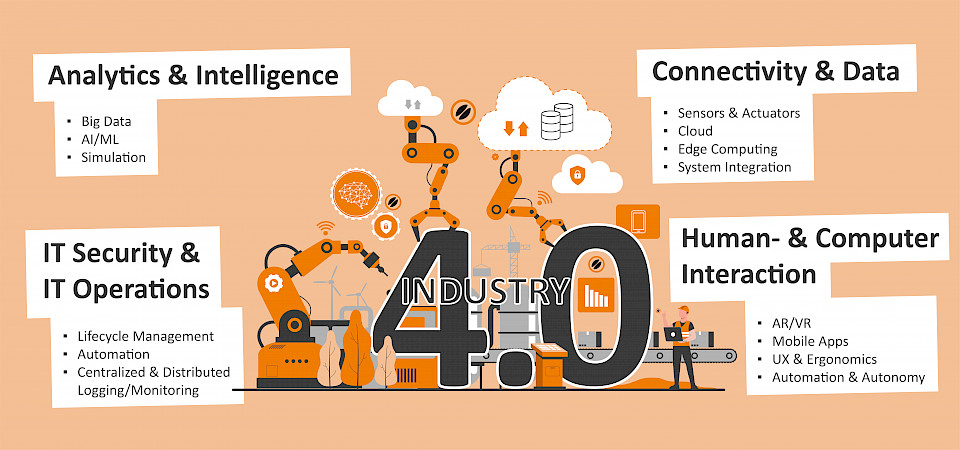

Industry 4.0 is the intelligent networking of machines, people, and industrial processes. Innovative information and communication technologies are often used to enable communication between machines and between people and machines. Basically, it is always about networking the existing machines, processes, and people in such a way that the overall system delivers the maximum added value. At jambit, we have identified four building blocks in this context, which together constitute an Industry 4.0 system:

Since Industry 4.0 systems are critical to success and must be operated reliably and securely, IT security and IT operations form the foundation. Building on this, the connectivity & data module covers the connection and networking of machines and possible data pre-processing in edge computing, right through to the transfer and storage of data in the cloud. Based on this data, analyses can be carried out, also with the use of advanced algorithms.

The mere ability to collect, understand, and evaluate data already makes it possible to increase flexibility in the value chain. Even if machine automation is already working well to a large extent, humans remain a central component in an Industry 4.0 system. People and machines interact with each other and with new technologies that enable remote control, for example.

The approach is used in all industries that want to digitize their products or their production process, or create digital value-added services for their products. Industry 4.0 is a collective term for various concepts and technologies with the goal and potential to revolutionize industrial production once again.

As a software service provider, we at jambit address all four building blocks of the I4.0 system and work with our clients to develop customized software solutions that enable measurable optimization.

Industry 4.0 – making production simpler and more efficient

Due to international competition and increasing market pressure, industrial companies want to avoid waste and inefficiency wherever possible. The Industry 4.0 approach therefore aims to make industrial production or the production process simpler or more efficient to identify cost drivers. On the one hand, it focuses on machines and IT, and on the other hand, in the spirit of lean production, on processes and people.

The often mentioned smart factory is characterized not only by networking but also by transparency, which enables the optimal use of resources. In this way, an optimal interaction of procurement, production and distribution can be achieved.

All technical solutions of an Industry 4.0 approach should always solve a real problem and create a tangible improvement. In the following, we present use cases that illustrate the possibilities of the I4.0 approach.

How to build an Industry 4.0 system?

jambit analyzes, consults, and implements customized solutions

Existing industrial systems are often not designed to transform into an Industry 4.0 system without obstacles. The amount of data is often a challenge itself. jambit has proven experts in the areas of Big Data Engineering as well as AI, VR/AR and IoT development, who have specialized in exactly these technological areas.

We see it as our task to analyze systems and, if necessary, to place the architectural core on new technological feet. In doing so, we take care to adopt and integrate components that prove to be viable for the future. Our experience shows that industrial systems always have a past. They are used, they continue to be used productively, and they cannot and should not be replaced from one day to the next.

The way to an Industry 4.0 system is often a transformation. jambit combines the knowledge from different industries and from many transformation projects with profound IT know-how. In some cases, we rely on industry standards and we use innovative, new technologies in others. In doing so, we rely on cross-functional high-performance teams of generalists and specialists to develop individually customized solutions for individual problems.

Looking for a competent service provider for your industry 4.0 project?

Contact us now!