Süddeutsche Zeitung - Development of auction platform Kaufdown

Open navigation

Open navigation Services: Frontend development, backend development, software architecture

Development period: 2018 – today

Technologies & methods: Java 17, Spring Boot, React, TypeScript, Piral, Maven, Node.js, PostgreSQL, MongoDB, RabbitMQ, Microsoft Azure, Scrum, DevOps

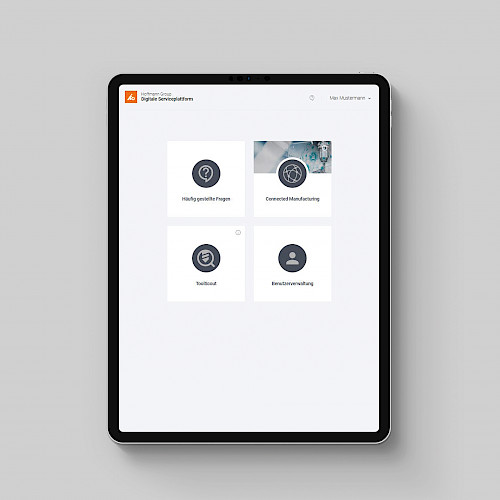

Together with Hoffmann Group, jambit is developing a service platform in the field of digitization in manufacturing. The result is a customer portal that displays various digital IT products for users in manufacturing. Applications range from simple user management to comprehensive products such as Connected Manufacturing, which enables digitization of tool management in the manufacturing industry.

jambit accompanied the Hoffmann Group in the middle of the paradigm shift towards microservices. Microservices are a method for writing software in which applications are broken down into smaller and independent components according to their responsibilities. This idea can also be transferred to the frontend, for example for faster software development and better customer orientation. With microfrontends, different teams work on different projects and can add services independently of each other and therefore scale easily. The jambit developer team also established best practices for the further development of Microfrontends on the platform. In addition, the jambit team supported the redevelopment of an internal content management system for the automated management of all the platform's application. Starting in 2022, jambit is also working on the redevelopment of a web application for administrative tasks of the digital service platform. Furthermore, jambit is to work closely with the client's internal developers on the further development of the backend architecture in the future.

The coordination during the project takes place between many different partners. Both in personal contact and via digital channels, jambit is able to live a productive and open communication style with the Hoffmann Group. jambit also advised as one of the pioneer organizations in the project during the introduction of Scrum and established DevOps practices.

The frontend was developed as a customer portal for users in production and therefore had to meet special requirements in an industrial environment. In addition to user administration, the frontend consists of a dashboard that can be used to launch various solutions. These include ToolScout, Connected Manufacturing and the Workstation Configurator. Tool Scout enables users to find suitable tools for upcoming production steps quickly and easily and, if necessary, to reorder them via the Hoffmann Group eShop. The Connected Manufacturing application enables production employees to manage tools and production orders. Companies maintain a clear overview of production and simplify workflows, as the platform reduces search and waiting times. In addition, employees can better plan the use of tools and their capacity utilization.

The Hoffmann Group is an industry expert in trading and manufacturing of tools, operating equipment and personal protective equipment and offers the associated consulting and services. The digitization of customer relationships is one of the company's key tasks. Our project, the digital service platform, is a building block of this strategy.

With the digital service platform, Hoffmann Group is creating a new offering for its small and medium-sized business customers. They need digital manufacturing solutions that are tailored to their specific needs. In addition, they often do not have the resources or know-how to set up a large-scale project to digitize manufacturing. The customer portal, for example, enables companies to manage their user profiles, roles and rights independently and to use various digital manufacturing solutions via a single account. jambit developed a high-performance, modern backend for the portal to provide services and information. Hoffmann Group becomes a provider of a digital service platform and advises its customers with a concrete solution for digital manufacturing.

Contact us now